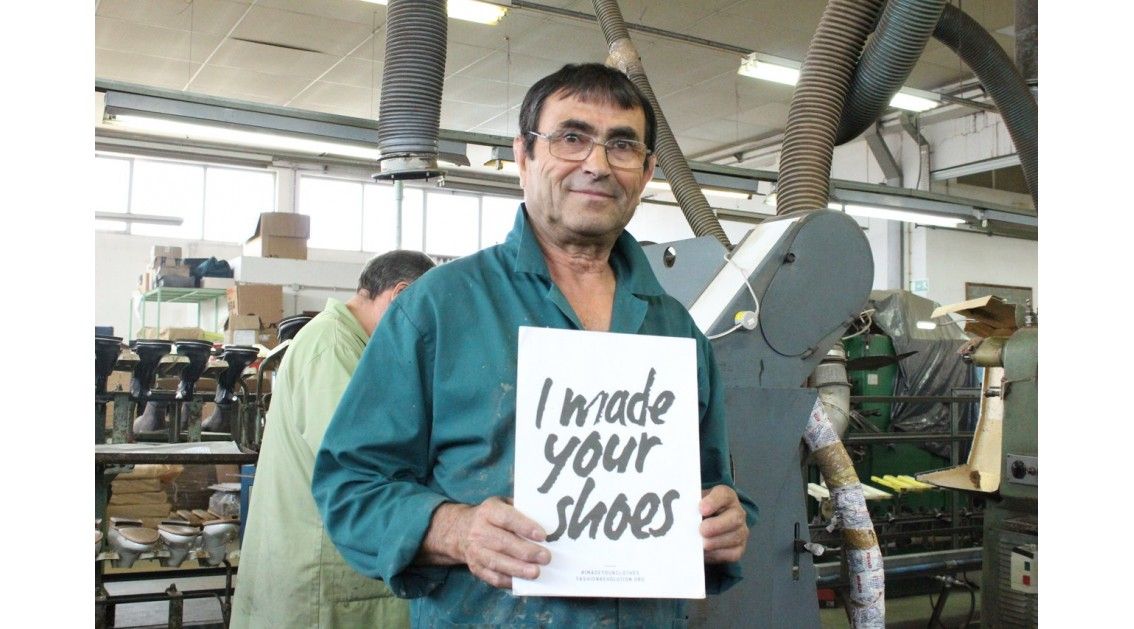

Transparency in the way we manufacture our pieces, is what we stand for at NAE. Where do the materials come from, who processes them, and how they are handled at the factories. All these steps are important, and the people and lives involved matter.

In Fast Fashion, the price is paid by workers that do not know human rights, by children with no childhood, and by land, that used to be full of life, destroyed, so that profits keep increasing, and retail prices stay the lowest possible.

In order for some to have excess, other get nearly nothing. This system isn’t only tortuous for people and animals, but also for the planet that is our home. It is of great importance to break this cycle.

How?

By choosing Slow Fashion. Prices may not be as attractive for the consumer, but the quality is far superior. The idea is that the product that is being sold, lasts the longest possible, and is manufactured in an ethical and environmentally friendly way.

These are the ideals that we follow. And that is why today we are going to take you to one of the factories that we have worked with for the longest time, Trofal. It was one of the first ones to accept the challenge of working in a sustainable way, with vegan materials, before it was « trendy ».

Trofal – the family company that survived the crisis, by following sustainable production models.

Mr. Luís Couto opens the doors of his factory, founded by his grandfather in 1903. That was a time when shoes were handmade, and their focus were typical south Portuguese boots, strong and resistant. Alongside his father, and only with 18 years old, he transformed a small business into a company. Unfortunately, his father passed away not long after.

Mr. Luís Couto was left in charge of the entire company and decided that he would always choose the most up to date solutions. He always tried his hardest to work with natural and eco materials, even though it wasn’t a popular concern.

L.C “We always worked with market niches, the most technical pieces, the eco-friendliest possible (…) today people talk a lot about circular economy, and without knowing the term I was already doing it.”

It was the first Portuguese company, within this branch, to get the ISO 9001 certificate, and the 3rd in Europe. This shows a will to stand for excellence and good practices. In Trofal, the production’s quality and precision are the key. That is why they choose to work by the Goodyear Welted standarts. This means that everything is sown in- and outside, with a cork isolation and no agressive glue. The absolute most environment friendly process.

L.C “The sole is filled with 4mm cork, in a plaque, that is sew to a rubber sole, made out of recycled tires. (…) Any European country will ask for Goodyear Welted, which is the old way, when everything was made by hand, and then it became the process of military boots, that needed to be very resistant, comfortable and to absorb sweat. Nowadays it’s your average shoe. And now we were able to add the sustainable and eco part.”

Even though it costed more, and few people looked for this way of making shoes, Mr. Luís insisted and persisted, and today is praised for choosing the Slow Fashion path.

It’s important to understand the economical and emotional effort that factories like Trofal must endure to be able to compete with Fast-Fashion. Supporting businesses like this is fundamental for a thriving future. This support should be on political agendas, but it should also be reflected in the way we buy.

Fast Fashion vs Slow Fashion

Mr. Luis used the example of a Fast Fashion factory, so that we can comprehend the disparity between the two. A fast-fashion factory, in other words, a mass production factory, produces 10 times faster. The shoe arrives in parts, like a car, and all they do is glue it all together. Meaningless to say that the used glues are the fastest to dry, and the cheapest, therefore the most toxic ones. The materials used derive mostly from the most toxic plastics like PVC. The result are cheap shoes, in which the quality is far inferior and the environmental impact far superior.

However, the differences don't end there. Mr. Luis sees the people who work for him as a family. He tells us that he has people working for him since the very beginning, 40 years ago. He describes with special care, the constant reunions with the employees, so that they can be up to date on what's going on with the company, and so that they can give him the best feedback possible.

This is only possible in small or medium sized businesses, through human and selfless values.

Difficulties in the shoe business

Of course there are still a lot of problems to overcome. The lack of young people interested in the job, being one of the most pressing. "Young people don't want to get their hands dirty." That's something he referred to us a lot. The reason, he believes, lays in the fact that many technical degrees were shut down a couple of years ago . It's urgent that society values factory work, because we are certainly losing talented people by continuing to judge a job by its offices appearance.

Moreover, at Trofal, innovation is something that is always pursued. It's not at all boring and stagnant! When there weren't any vegan materials available, mr. Luis travelled to Hong Kong' fairs to find micro fibers. Imagine that adventure, looking for rare materials in a time when the internet wasn't what it is today.

Nowadays that doesn't happen anymore, the market in Portugal and in Europe us unrecognizable. It's possible to find all the vegan materials we want without leaving the comfort of our home. About the Portuguese market, mr. Luis believes that it's important that we focus on making quality pieces and accepting small series of products. Leaving large amounts for countries like China and India, against whom we can't compete.

11 years ago, veganism wasn't as fashionable and vegan shoes almost impossible to find. However, Mr. Luis Couto accepted NAE's challenge.

"The first boot NAE ever released (with Trofal) was based on a best seller from our company. In the beginning we sold thousands of them to France. (...) The challenge was to make the same boot, but vegan. We were able to do it using microfiber, with a rubber sole and some of the components were recycled."

We couldn’t leave without asking Mr. Luis, which was his favorite material to work with:

"It has been 20 years since we started working with vegan products, and the changes are amazing. Nowadays it’s easier to work with such products. It took a lot of research and our feedback, the shoe making industry, to perfect them. (…) The goal is to give comfort and durability, in an eco-friendly product.”

Work with NAE

The partnership with NAE lasts since 2008, and it’s with pride that we celebrate 11 years of adventures in the name of ethical and sustainable Fashion.

Mr. Luís ends the talk with some words that evoke, with a certain nostalgia, NAE’s origins, in a time when the vegan universe was far from the Fashion world.

“To me it was a great pleasure to get to know Alex and Paula. (…) they had defined the path they wanted to take, and they wanted to do it slowly. I think there was empathy, we did the firsts tests, the first samples, and we kept cooperating. We worked progressively. Both parts were open to it, because this is the only way to get a project to move forward.”

It’s with gratitude that we work with Mr. Luís Couto, and his daughter Miss Filipa Couto. Family companies like this are hard to find. The warmth they receive us with, and the strength with which they accepted and continue to accept our challenges, is absolutely stunning.

We hope that together, we keep making the world a better place, with less carbon emissions, less animal torture, less exploitations of human beings, much more upcycling, and a lot more love!

All we want is to emit good energies, in the shape of the coolest shoes possible!

Check the video below and have an amazing day,

NAE